Did you ever wonder where the quietest place on earth is? In the heart of the Mojave Desert? At the top of an Icelandic volcano? In the misty realms of Northumberland? If those rank indeed among the most tranquil places in the world, the most quiet place is none other than Microsoft’s anechoic chamber, located at its headquarters in Redmond, Washington. Quite a prosaic let-down, you say? Not so fast.

This place, recognized in the Guinness Book of Records as the quietest room in the world, was measured as having a background noise of -20.3dB(A)—that’s 20 dB below the threshold of human hearing. What’s even more spectacular about this number is that -23dB is the quietest achievable level on earth, vacuum aside: it is the noise level made by air molecules bouncing off each other. And when it gets that quiet, the human ear adapts. People start hearing their hearts beat, their lungs breathe, their stomachs gurgle. In an anechoic chamber, you become the sound.

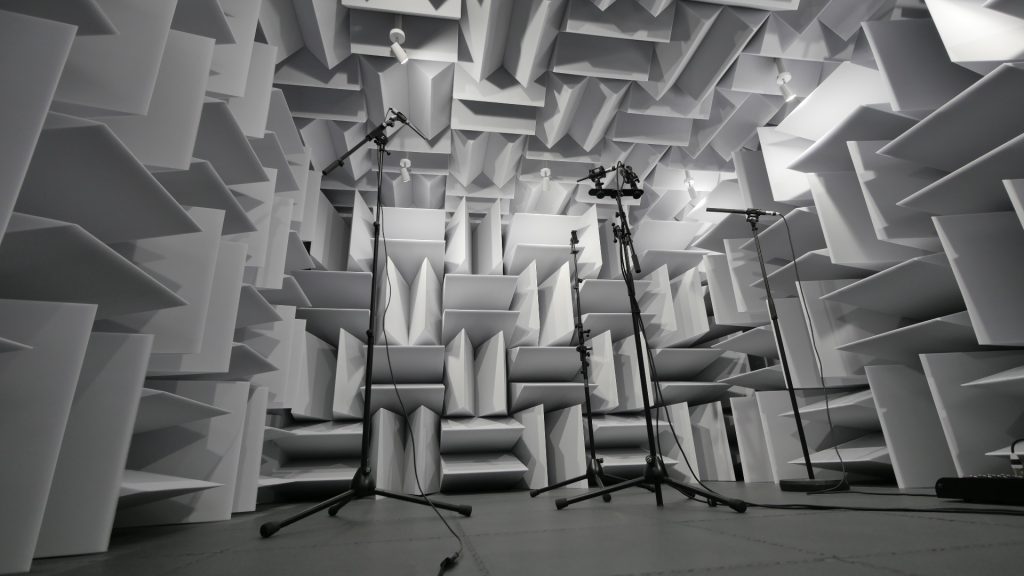

Of course, Microsoft is not the only company to own such a room: almost any manufacturer you can think of in the smartphone industry has an anechoic chamber. This is why, in order to replicate industry conditions, we undertook to build one for ourselves. Nearly six weeks and nine tons of materials later, here it is. Let’s take a peek, shall we?

The purpose of an anechoic chamber is to simulate “free field” conditions, in order to conduct acoustic measurements without the results being affected by the chatter of the cafeteria, by the highway roaring nearby, or—last but not least—by the room itself. (Yes, the room has a sound.)

Thus, as its Greek roots whisper, an anechoic chamber is not solely built for phonic insulation from the outside world: it also has to cancel the internal reverberation generated by the walls, floors, and ceiling of the room.

To absorb acoustic reflections, every inch of the internal walls is covered with 800mm pearl-gray melamine wedges that are capable of breaking sound waves by trapping them before they get a chance to bounce back towards the room.

To be precise, ours is a semi-anechoic chamber: while we have also mounted 200mm wedges on the ceiling, the floor is solid, acting as a work surface for supporting heavy items. However, in case we need “fully anechoic” acoustics, it is always possible to cover the entire floor with 300mm wedges—an operation which would require only two technicians and less than 20 minutes.

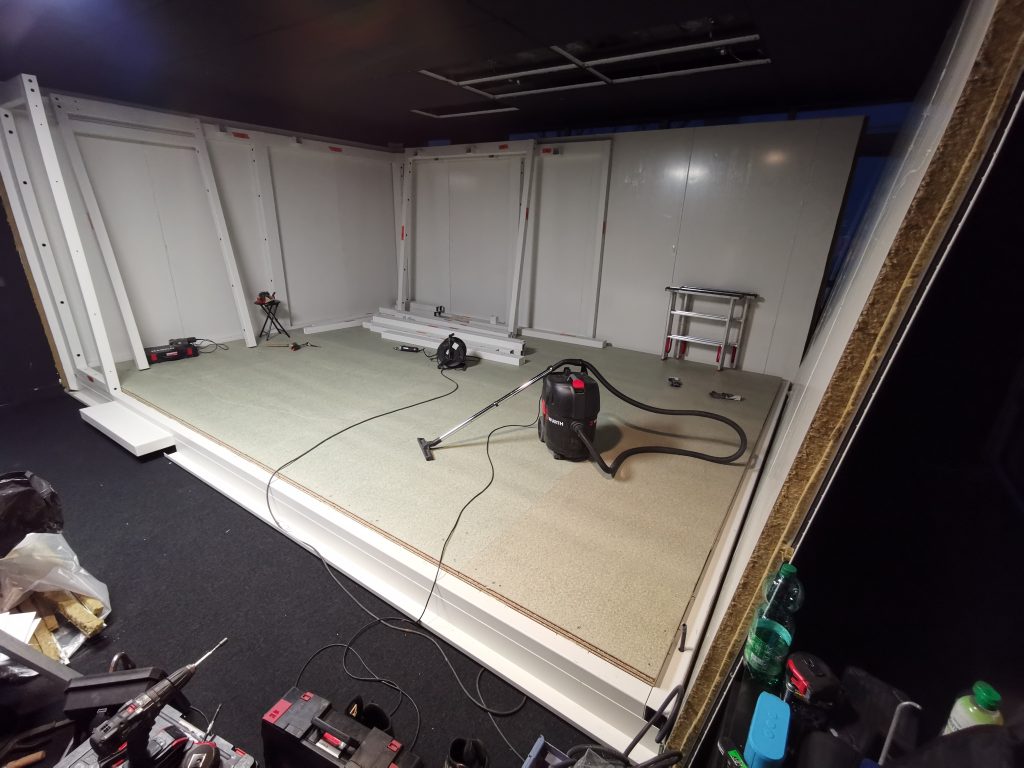

The floor floats on some sixty vibration-damping pads, called bushings or shock mounts. This system helps isolate the room from solidian noise—in other words, from structure-borne vibrations.

Finally, 200mm-thick walls composed of steel and various types of stone wool minimize airborne sound. While the exterior shell sits atop 28 square meters of shock mounts, the interior surface, factoring in the melamine wedges, offers about 10 square meters of treasured quietude for the measurements to come. Here’s a timelapse of the construction process:

DXOMARK encourages its readers to share comments on the articles. To read or post comments, Disqus cookies are required. Change your Cookies Preferences and read more about our Comment Policy.